I must admit my first resin 3d printer left me underwhelmed. I just didn’t get it.

All of the extra process and mildly-toxic material handling didn’t seem worth it to me. I felt like the build plate was tiny with limited utility. It also seemed easier to screw up and make expensive mistakes. Like, printing a Cinderella castle in an orientation where the extremely sharp parts puncture the film. (ahem) Though, I had a specific use case for a transparent part and the printer serviced that need well enough.

I’d likely have felt differently if I was into tabletop gaming but alas, that life is not for me. Not for lack of interest, my family and work schedule seem consistently too restrictive to allow for multi hour gaming sessions several times per month. I’m jealous, really.

Size Matters

Large format resin printing brought the utility and flexibility I was looking for to justify the extra processing. For parts that required a uniform translucent material, resin is a good answer. Resin is great for sub-millimeter accuracy. Resin also expands your toolbox of material properties with some cured resins exhibiting characteristics of ceramics rather than typical thermo-plastics but easy use of ABS-like resins when that is your need.. Most electroplating services can be dubious of filament for fear of spoiling their acid baths but happily accept resin parts. For prop-making, I’d often found myself using high-infill rates or building sand/concrete-pour channels to add weight to FDM-printed models. Making a resin print solid doesn’t require any infill pattern shenanigans that might introduce seams or sacrifice the surface quality. When making batches of parts, the ability to run large plates of parts is really nice.

Because of these characteristics and a side-adventure into prop making, within six months I had a significant amount of the Elegoo outer solar system represented in Resin printers. Two Elegoo Saturns, two Elegoo Jupiters and a Phrozen Mega 8k on pre-order.

Having spent some time with all of these printers, these are my notes.

Saturn Ultra

The Saturn 3 Ultra is a good machine. In many ways the advertised 12k resolution was more gimmick than practical. The ability to issue print jobs over the network from within Chitubox was nice. The Saturn 3 Ultra’s network printing features are pretty basic, however. Closer to “drop a file via sFTP” than a tight integration with full machine and job management and status callbacks. Network printed files get uploaded to the Saturn’s local storage which is limited and fills up pretty easily, requiring intervention.

The 12k panel costs more to replace and the results aren’t significantly better than every other printer in this class. The black hood looks nice. No hood would be better. The mask LCD is attached to the surrounding frame with adhesive which makes replacing the panel and re-leveling for accuracy somewhat of a pain.

Ultimately, my chief complaint with this printer was the limited build volume. (218.88x122.88x260mm)

Elegoo Jupiter (OG, 6k)

To answer the need for volume, I ended up moving to the Elegoo Jupiter 6k. An absolute workhorse, the Jupiter is massive - about the size of a dorm fridge and twice the weight of such. I liked this printer so much that I went off and bought a spare, having grown to rely on it. The 277.848x156.264x300mm build volume brings alot of utility opening up for some massive prints.

The metal-box construction includes two USB ports and still has an optional punch out for exterior ventilation. The O.G. Jupiter didn’t include wireless capability and I found it to be picky about USB thumb-drives. It didn’t perform well with my Sandisk drives but is rock solid with these PNY thumbdrives.

The LED light in the cabinet is quite handy.

Door beats hood, every time. It is so very nice to not have to find a place to stash a hood every time I removed a print. The tinted plastic does a reasonably good job of keeping UV out but since I operate these in an open garage I still opted to attach blackout cloth with magnets whenever resin is in use. Sustained, direct UV will penetrate that tint. Speaking of UV leakage, Elegoo seems to have made no attempt at preventing UV leakage from the lightsource in the machine. The fan vents let alot of the UV out, so keep this in mind if you have nearby uncured resin.

The taper-design of the build plate works well to keep resin from pooling above the plate. The vat is well built with so.. very.. many set screws. The vat includes a clever bottle-refill attachment that I’ve literally never used but appreciate the simplicity.

Leveling is achieved with 4 horizontal set screws. I found leveling to be pretty easy but a common complaint is that over-tightening the horizontal set screws can engage the threads beneath and bring it out of level. If you experience this - put airsoft BB’s in the set screw hole to act like plastic bushings.

I’m not really sold on fast-printing or fast-resins but the Jupiter is effectively twice as fast as the Phrozen Mega 8k. The default resin profiles for the Jupiter have two-stage lift speeds of 65mm/min accelerating to 180mm/min. You can sort of think of the Jupiter as a larger, heavier, Saturn 3.

I think the current standard for fast resin printing is 300/1000 mm/min.

Reliability

In my experience the Jupiter has been a reliable machine. My main unit ran in the garage with an almost-commercial workload of 1-2 bottles per day from Fall of 2023 through the Summer of 2024. From cold winter nights and blistering hot summer days, it just ran. I only ever had to use the spare machine for a few weekends to get caught up. I have encountered two failures with these machines.

Screen Failure

In late July, after hundreds of kg of resin in this one machine, it had a screen failure. The failure didn’t seem to correlate with any particular print failure but it was insanely hot at the time. I suspect that the cause was de-lamination inside the LCD panel itself.

The replacement panel was $180 shipped directly from Elegoo and was extremely easy to install. Unscrew the mounting screws, attach the ribbon cable and re-fasten the mounting screws.

MOSFET FAILURE

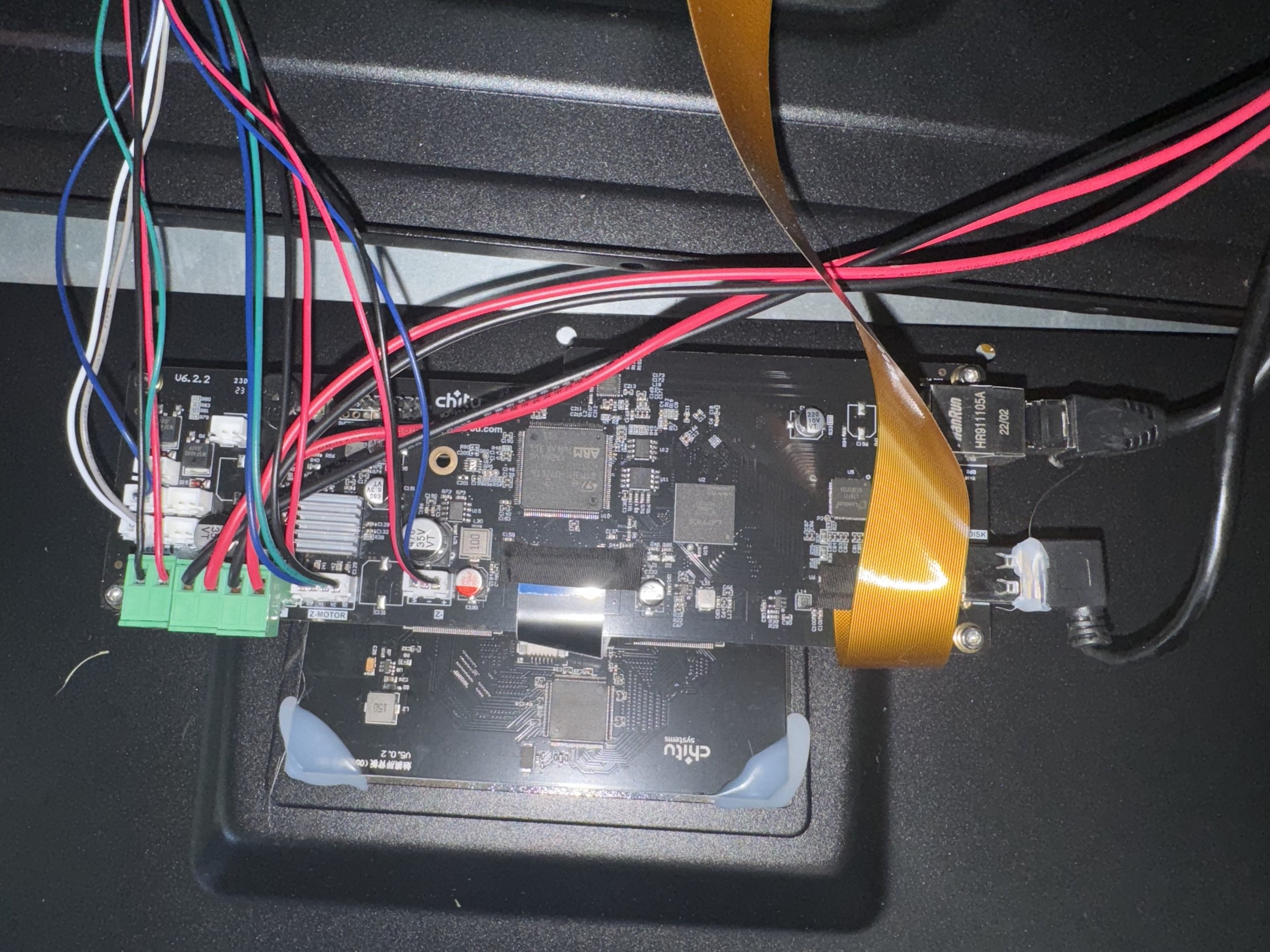

I switched my remaining workload to the backup machine, which was more or less new by comparison while waiting on the replacement parts. This machine experienced a failure, symptomatic of the UV light remaining on regardless of machine state. Evidently, this is a common issue and relates to a MOSFET (like a transistor) shorting to remain on. Here is a pretty good blog post about it: https://blog.honzamrazek.cz/2021/06/fixing-the-backlight-always-on-problem-on-elegoo-saturn/

The machine was still under warranty but I also ordered a spare mainboard for $58 from Elegoo.

Elegoo’s Support Experience

In southern terms, I’d put Elegoo support in the “bless their hearts”, category. I think they mean well and eventually they arrive at the right solution. My biggest complaint is the same complaint I have with most 1st-level tech support experiences: They waste alot of time. You can email support on one business day with a dense but thorough set of troubleshooting steps and some direct and reasons observations. A day later, expect a boilerplate response that has you repeating steps already covered in the first email.

You must jump through the hoops but once you do they tend to stand behind their products and out of warranty parts are reasonably priced.

Phrozen Sonic Mega 8k

The Phrozen Sonic Mega 8k sports a 15” masking LCD screen and ample build volume of 330mm x 185mm x 400mm. Phrozen’s perforated build plate design is meant to reduce suction during retract. Reading reviews, I was concerned that this flat build plate design might lend to issues with resin curing in the holes but thankfully that hasn’t been a problem.

The V2 model of this printer introduces an integrated drip hanger and there are open source models and etsy sources for retro-fit plate drip hangers to work with the V1 version of the printer. I do recommend using one just be careful to use appropriate material if you print your own. Having the plate crash down into the VAT has the makings of a bad day.

Unlike the Jupiter, the Phrozen Mega 8k build plate comes factory leveled and I’ve found their factory leveling to be very good.

The cabinet door design has its pros and cons but I broadly like it. There are more (and more powerful) cooling fans inside the Phrozen Mega 8K to keep the light source and PCB well ventilated. The PCB, Panel and Touch screen are also sourced through Chitu Systems, which provides piece of mind in the event something happens with Taiwan=based Phrozen’s ability to supply parts and upgrades.

The Phrozen Sonic Mega 8k’s $3200 price tag is pretty steep for a resin printer and seems extreme if you consider the Elegoo Jupiter and AnyCubic Max line of printers. I will say that the Phrozen support experience has been very good, though I still experience the typical lag in responses due to their offset in operating hours.

The Phrozen Mega 8k isn’t a fast machine. I find that it is easily about half as fast for the same jobs as the Jupiter. I suppose the printing profiles could be tweaked to eek out additional performance.but I’ve been very hesitant to do so. This printer is consistent but the extra time focuses the use case, for me anyway. I could make 1 Dial of Destiny prop per day with a Jupiter printer but the same job takes 2 1/2 days on the Phrozen, based on the current profile defaults. This speed is okay for my use case that favors quality over quantity but if you plan on cranking out many parts often, you may consider a faster printer.