My basement floor is a nightmare hell-scape for pinball glass. The hardest of hard concretes with a rough brushed finish. I haven't broken a sheet yet but I'm always skiddish of the coming shard-po-calypse when I do.

You don’t eat yellow snow, you don’t eat tug on superman’s cape and * you never buy pinball glass in single sheets.

* Unless maybe Invisiglass or PDI Glass where you can reasonably only afford one at a time.

I usually try to bring home spare sheets of playfield glass from Marco when attending SFGE. When ordering by mail, Pinball Life has shipping pinball glass down to a science. Shipped two-at-a-time, they are well padded with ginormous foam corners. Those foam corners are great for shipping but at roughly 4in wide by 6in length, they are overkill for storing spare sheets.

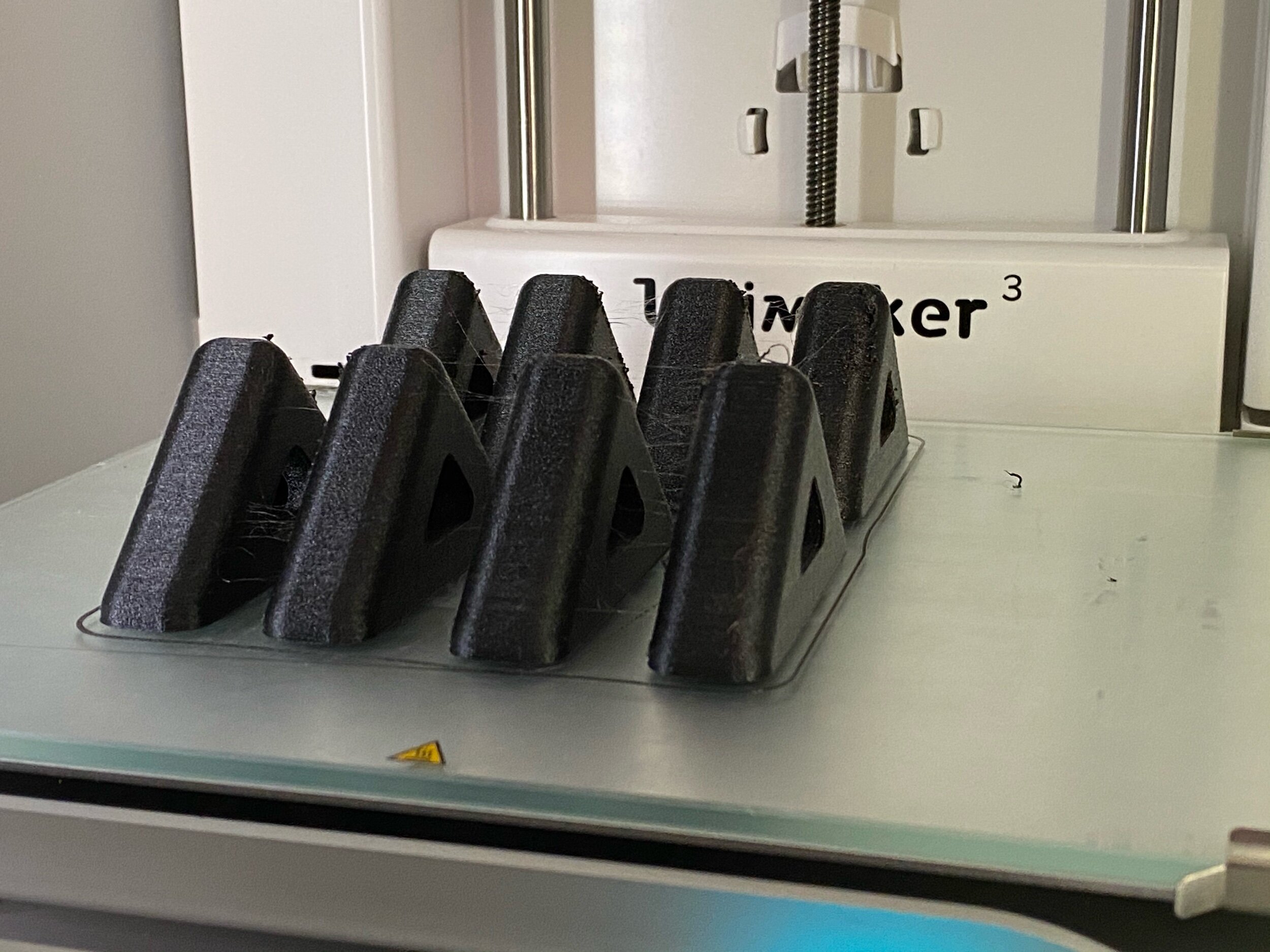

I found this clever 3D print design for a compact but effective solution for pinball glass corners. He designed the print to be used with TPU95A filament, which is a rubbery-plastic about the consistency of a dog bone chew-toy. The design worked well in that it grips the glass and provides a little cushion in a compact size.

TPU95A is the way to go for these. For invisiglass I might scale up by an inch or two in length and height but keep the same thickness for grip. If you print them on PLA, you will want to scale them up as well, uniform scale of 115% will do the truck. I understand the drive to use PLA, I’ve received glass with plastic corners before but if you have TPU available - go that route.

Thanks to 80sPinTech for a good design!