I got into 3D Printing, late. During the pandemic shutdowns I was inspired by all of the ingenious solutions and crowd-sourcing of missing ventilator parts, masks, shields and supplies for first responders. I blogged about my choice in 2020, the Ultimaker 3.

Since that time I came to appreciate the stability, resiliency and reliability of the Ultimaker but I also became weary of their price point in newer models. I also found the use of 2.85mm filament to be limiting in some ways. At times, I wanted to build a second printer for concurrent print runs but most printers that fit my needs used the more common 1.75mm filament.

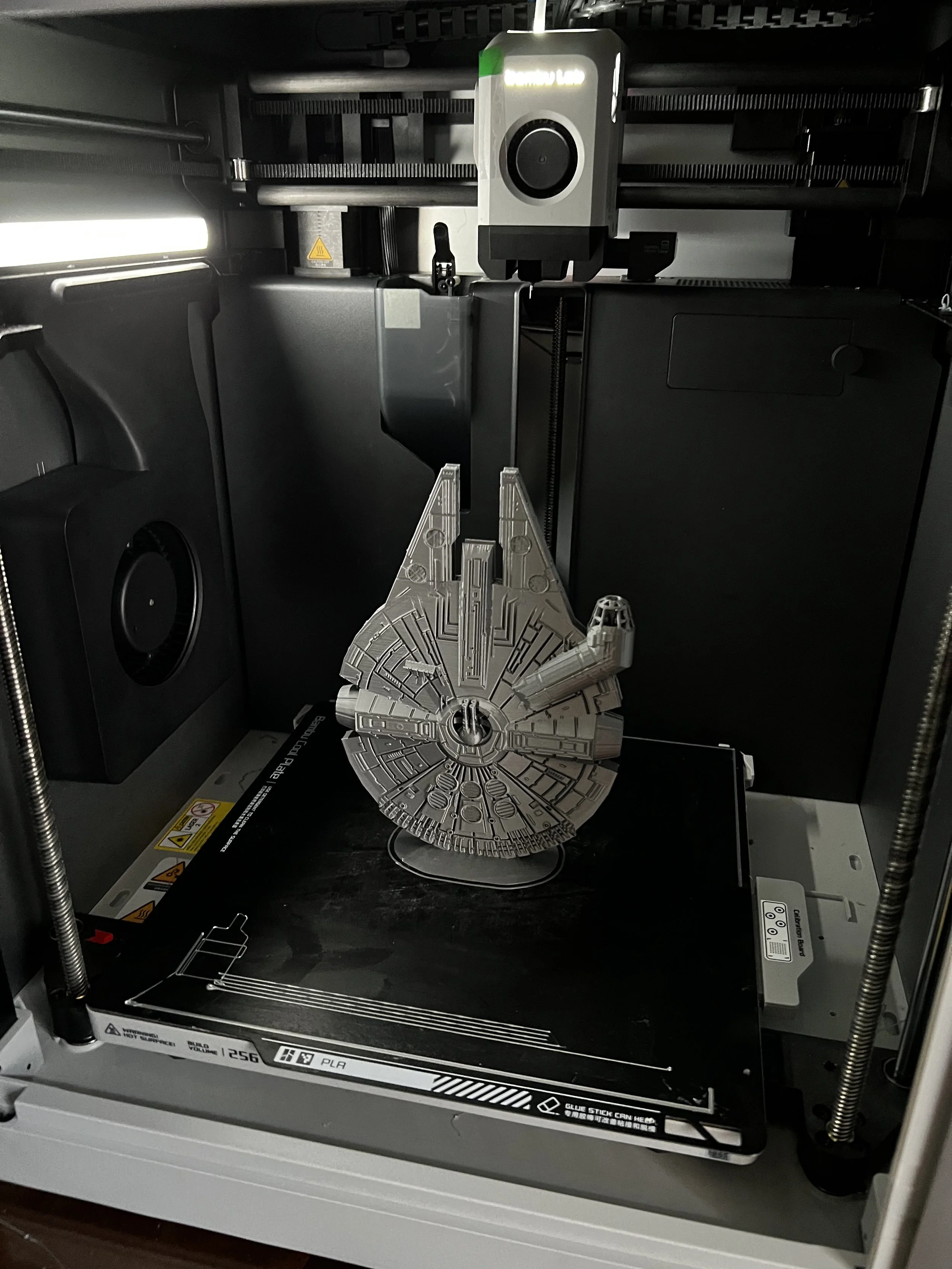

Well, I finally decided to take the leap and move to a different printer for primary jobs and prototyping.

About the Bambu X1

The Bambu X1 is a reasonably new middle-priced entry to 3d printing. After starting in a kickstarter-esque preorder scheme, the printer received pretty glowing initial reviews for being fast and well equipped with features.

AMS

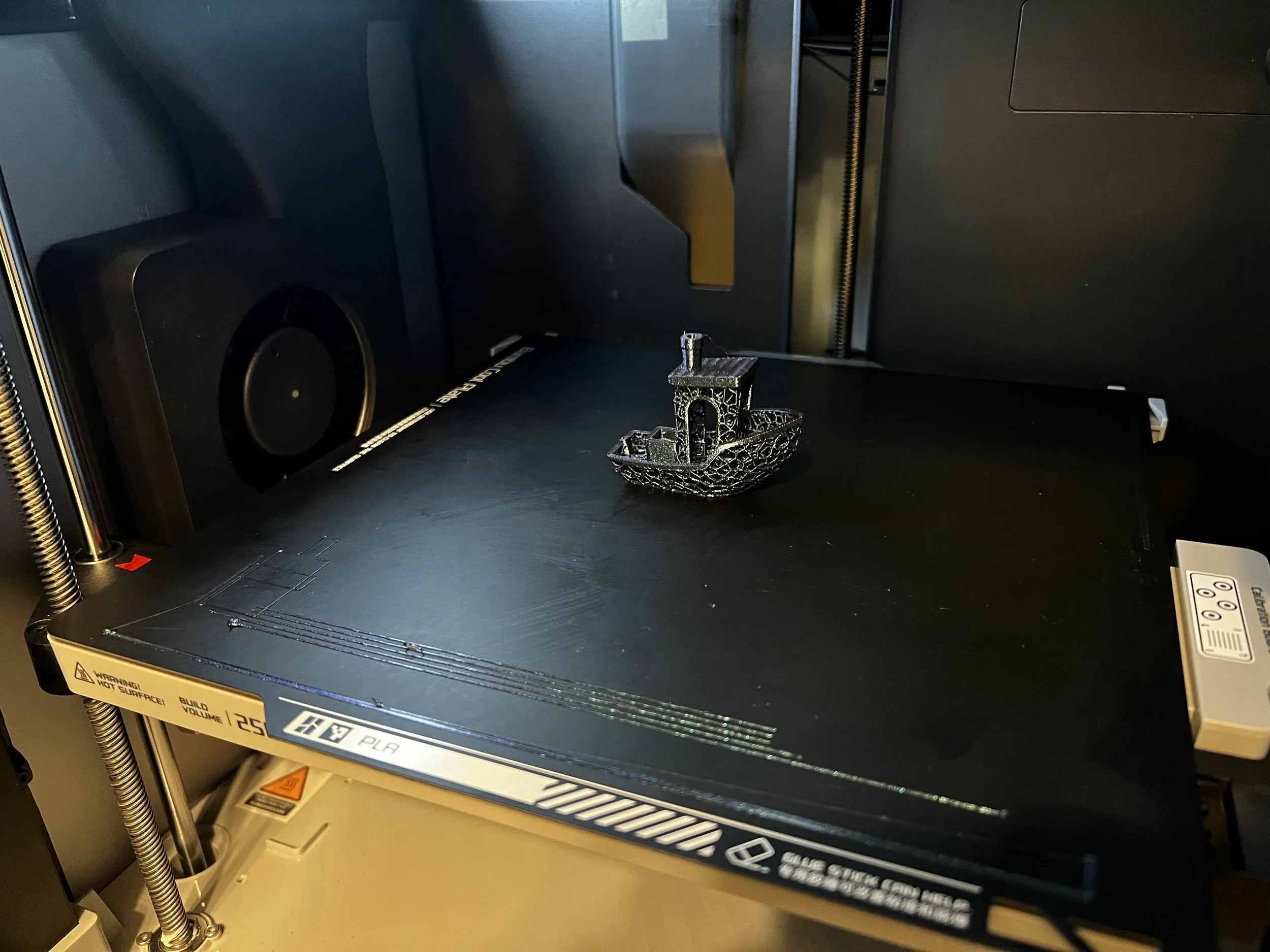

The Ultimaker supported dual filament printing through Ultimaker’s dual-extruder print core design. Two feeders would feed filament from spools in the back of the machine to one of two hot ends in the print head. Bambu’s answer to multi-filament printing is AMS. Think of AMS as essentially a multiplexer for filament.

I’m not really interested in writing a full review here there are 100’s of 3d printing sites, channels, blogs and groups where you can find meaningful review. My short update for now is: I Like It. At times I miss the glass build plate and I wish Bambu would have invested in a dual channel / two hotend design to cut down on waste in filament changes. Aside from that, I’m really impressed with the speed to quality ratio of the X1C.